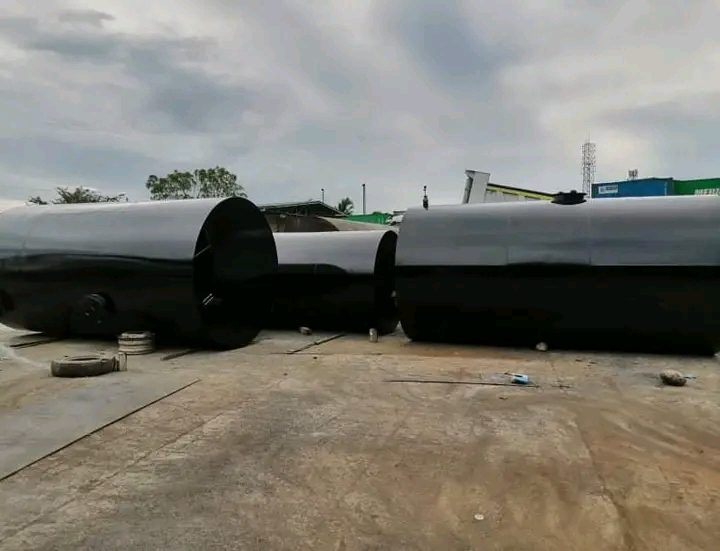

Under Ground Tanks

Horizontal cylindrical single and double-walled tanks for underground storage of flammable and non-flammable liquids. Made by using shell plates and dished ends made in carbon steel type A36 complying with UNI EN 10025.

The external shell is welded by submerged arc welding procedure while the internal part is MIG-welded where necessary Parts are designed in compliance with rules and regulations in force.

Single-walled tanks form an impermeable containment; they act as the inner tank of double-walled tanks.

Double-walled tanks; for these tanks, a secondary wall is welded around the inner tank, which forms an impermeable self-contained tank. These tanks are provided with two sockets for the leak detection system in order to permanently monitor the integrity of the tank.

All tanks are hydraulically tested. Tests are pressure tests and are performed to check the inner tank and the interstitial space between the inner and the outer tanks as well.

Fields of application:

Single-walled tanks are mainly used for:

- Fire-fighting systems.

- Irrigation systems.

- Collection and storage of rain water.

- Drinking water storage.

- Collection and storage of waste and effluent water.

- Storage of all kinds of liquids.

- Service stations.

- Private fuel stations.

- Storage of flammable liquids for heating systems.

- Feeding generators.

- Storage of aircraft and ship fuels.

- Storage of chemicals and water-polluting liquids.

- Collection and storage of lubricants and drain oils.

- Collection and storage of waste and effluent water.

Each tank is provided with an external protection coating which also acts as cathodic protection.

The external coating of each tank undergoes a high-voltage test in order to prove its integrity.

EPOXY-TAR: coated externally with epoxy-tar paint consisting in an epoxy-based, 2-component product made with epoxy resins modified by a coal tar-based hydrocarbon resin.

FIBERGLASS (GRP): steel plates are sandblasted (SA 2.5 – ISO 8501-1) and coated externally with a reinforced fiber-glass coating.Internal coatings:

When an internal coating is required, tank’s inner surface is prepared in accordance with the customer’s requirement and the coating manufacturers specifications to ensure permanent adhesion of the selected coating. On request we can provide the following internal surface coating:

- Internal coating for non-drinking water: steel surface is sandblasted (SA 2.5 – ISO 8501-1) and coated with an anticorrosive layer of epoxy-based two-components resin.

- Internal coating for drinking water: steel surface is sandblasted (SA 2.5 – ISO 8501-1) and coated with a bicomponent polyammine epoxy coating which is certified by the Ministry of Health for prolonged contact with drinking water and food.

- Internal coating for aviation fuels: steel surface is sandblasted (SA 2.5 – ISO 8501-1) and coated with a light coloured epoxy-phenolic resin free from zinc, cadmium and copper alloys.

Underground storage tanks are a viable option for your fuel, chemical or oily water storage. Safety, fire codes, aesthetics, limited available real estate for distance requirements, SPCC compliance or even fear of vandalism or tampering, these are all factors when you’re planning fuel or hazardous material storage. The EPA regulates the type of tank that can be buried. The Carbone mild steel tank design meets and exceeds those regulations for underground petroleum and chemical storage.

When it comes to steel storage tank manufacturers, our underground tanks provide the ultimate in structural strength and compatibility for biofuels and additives, such as our single skin and double wall tank installed for underground fuel tank storage and other applications.

Are you Planning to Build a Fuel Station?

Are you having to store fuels required for daily use in a fuel gas Station?

Our underground steel tanks provide superior structural strength and product compatibility. Designed to withstand the harsh conditions of the underground environment, they are serviceable for storing a wide range of petroleum products and other hazardous liquids. Tank dimensions and thicknesses are calculated in strict compliance with API Formulas for Stress and Strain as presented in UL-58 (Not listed). In addition, customization to suit your requirements is always available. A variety of industry-proven corrosion protection systems can be selected to be installed on our underground fuel storage tanks using a variety of backfill materials. Capacities from 240- 50,000 gallons, exterior full fillet lap joints, striker plates under every opening, seam inspection, and 5 psi factory air tests, our underground storage tanks are dispatched after rigorous leak testing .

Our underground tanks also come with FRP/ GRP linings externally to suit buried applications.

Shop Fabrications

Steel fuel containment systems have a proven history of providing reliable and safe storage of fuel products. With the addition of a fiberglass reinforced “FRP” outer, secondary containment layer the Elutron® fuel storage system creates a high performance, seamless and durable underground storage solution. The 360º interstice between the steel and FRP secondary containment is created by incorporating an aluminum foil layer which in turn provides a system for monitoring inner tank integrity. The steel inner tank provides the highest level of structural stability while the outer FRP layer provides complete protection from underground environmental conditions. The UL Listed Elutron® Double Walled Fiberglass Jacketed tank system meets the EPA 40 CFR subpart B, 280.20 standards for new underground storage tanks.

Orlandoh Steel’s Elutron® underground fuel storage tanks are compatible with water, gasoline, jet fuel, methanol and ethanol in varying concentrations, E 10, E-15, E-80, E-100 and kerosene commonly used in a variety of applications such as fuel stations, emergency power generators, and farm and residential operations and can incorporate multiple compartments. Installation of Elutron® diesel underground storage tanks is uncomplicated and due to the inherent, long term strength of steel are less dependent upon backfill for support when compared to non-metallic underground tank systems. Non-metallic underground tank systems require high-quality gravel backfill and a greater distance between adjacent tanks.

Each Elutron® system is supplied with a factory-established interstitial vacuum. Prior to delivery, our team cleans and levels all the fittings and marks the center lines on each tank. These details save installers several hours of work normally spent on the pre-installation testing and cleaning of non metallic tanks.

Quality is built-in to every tank system Orlandoh Steel fabricates and our production facility is certified and regularly audited by the American Petroleum Institute and Underwriters Laboratories.

Orlandoh Steel is a reliable partner with over 70 years of experience fabricating superior steel products including a wide array of storage tanks such as above ground fuel storage tanks, Fireguard® fire rated fuel storage systems, modular agricultural fuel storage tanks and petroleum storage tanks for oilfield applications.

QUALITY

- Every tank is tested per the UL standard 58+UL1746 to ensure it meets the specifications required by the National Fire Protection Association

- All of our welders are AWS certified

- Orlandoh Steel maintains a comprehensive Quality Management System that guides every aspect of our operations including sourcing, planning, and manufacturing processes

WHY ORLANDOH ENGINEERING®?

- 10 plus years of complex and critical steel tank fabrication

- American Petroleum Institute and Steel Tank Institute certified and UL Listed

- Orlandoh is dedicated to the highest levels of safety

- Unsurpassed customer support and commitment to on-time delivery

AVAILABLE ACCESSORIES

- Sump collars

- Manholes

- Threaded or flanged ports

- Deadman anchors

- Hold down straps

- Turnbuckles

- Submersible pumps